Quality Control

A 99.8% defect-free success rate proves our commitment to quality, precision, and excellence in every detail.

- Home

- Quality Control

Smart QC Workshop

Modern, Intelligent, Precise

Our state-of-the-art facility, which is outfitted with full-line AI-powered visual inspection technologies, can automatically detect color variance, surface scratches, and micro-defects in real time, guaranteeing that no mistake is overlooked. From raw materials to final assembly, every product is put through a multi-stage inspection process that is monitored in a hygienic, controlled environment to ensure consistent, dependable quality.

3-Stage Testing: See How We Ensure 99.8% Defect-Free Rate

Our commitment to excellence is evident in every stage of testing. From IQC to FQC, we integrate AI visual detection systems across all production lines, achieving an industry-leading 99.8% defect-free rate.

Rigorous Incoming Quality Control

Chemical Composition Analysis

Analyze quartz, feldspar, and kaolin for key oxides such as SiO₂, Al₂O₃, and Fe₂O₃ to ensure material purity and stability.

- Equipment: X-ray Fluorescence Spectrometer (XRF)

- Testing Standard: ISO 21068-1

Particle Size Distribution

Measure D10, D50, and D90 particle size values of powdered materials to ensure optimal flowability and sintering density.

- Equipment: Laser Particle Size Analyzer

- Testing Standard: ISO 13320

Glaze Adhesion and Strength

Simulate 300℃ to room temperature thermal cycling to evaluate glaze adhesion and prevent cracking risks.

- Equipment: Glaze Coating Tester

- Testing Standard: GB/T 3810.3

Colorant Stability Testing

Simulate 72 hours of accelerated light exposure to ensure a minimal ΔE color difference (≤1.5), guaranteeing vibrant and consistent surface coloration.

- Equipment: Xenon-Arc Aging Tester

- Testing Standard: ISO 105-A02

Slurry Mixing and Performance Testing

Every batch of raw materials is precisely mixed and tested for viscosity, density, and uniformity to ensure optimal flowability, consistent production quality, and exceptional slab performance. Detailed test reports are available upon request.

Strict In-Process Quality Control

Density and Thickness Testing

During pressing, the thickness and density of every slab are measured every 30 minutes to maintain structural integrity and ensure bubble-free compaction.

- Equipment: Laser Thickness Gauge, Ultrasonic Density Analyzer

- Testing Standard: ISO 10545-3

Moisture Control and Crack Detection

Slabs are continuously monitored to ensure optimal moisture removal in the drying process. Testing is conducted every hour to detect any surface cracks or shrinkage.

- Equipment: Infrared Moisture Analyzer, Industrial Endoscope

- Testing Standard: GB/T 3810.4

Temperature and Flatness Monitoring

Firing in kilns at 1200–1300°C, the slabs undergo temperature control with a precision of ±1°C to maintain consistent flatness and dimensional stability. Records are logged every 2 hours for comprehensive oversight.

- Equipment: Infrared Temperature Sensor, Laser Planeness Detector

- Testing Standard: ISO 10545-2

Glossiness and Anti-Stain Coating Testing

Completed slabs are tested for surface glossiness and protective coating uniformity. Sampling occurs on 5 slabs per batch to ensure bright, spotless, and stain-resistant finishes.

- Equipment: 60° Gloss Meter, Contact Angle Measuring Instrument

- Testing Standard: ISO 2813

Comprehensive Final Quality Control

Flexural Strength Testing

We apply controlled pressure to measure slab strength, ensuring each surpasses 50 MPa for slabs ≥12mm thick.

- Equipment: Universal Material Testing Machine

- Testing Standard: ISO 10545-4

Surface Wear Resistance Testing

By simulating extended wear, we ensure surface abrasion remains within ≤175 mm³, maintaining long-term durability.

- Equipment: Abrasion Tester

- Testing Standard: ISO 10545-7

Anti-Stain Resistance Inspection

Slabs are tested by exposing them to staining liquids for 24 hours, ensuring no penetration and ΔE ≤ 1.0 after cleaning.

- Equipment: Stain Testing Kit (Red Wine, Coffee, Oil, etc.)

- Testing Standard: GB/T 3810.14

Chemical Resistance Testing

Slabs are immersed in acidic (pH=2) and alkaline (pH=12) solutions for 7 days, showing no corrosion and gloss loss ≤5%.

- Equipment: Acid & Alkaline Solutions

- Testing Standard: ISO 10545-13

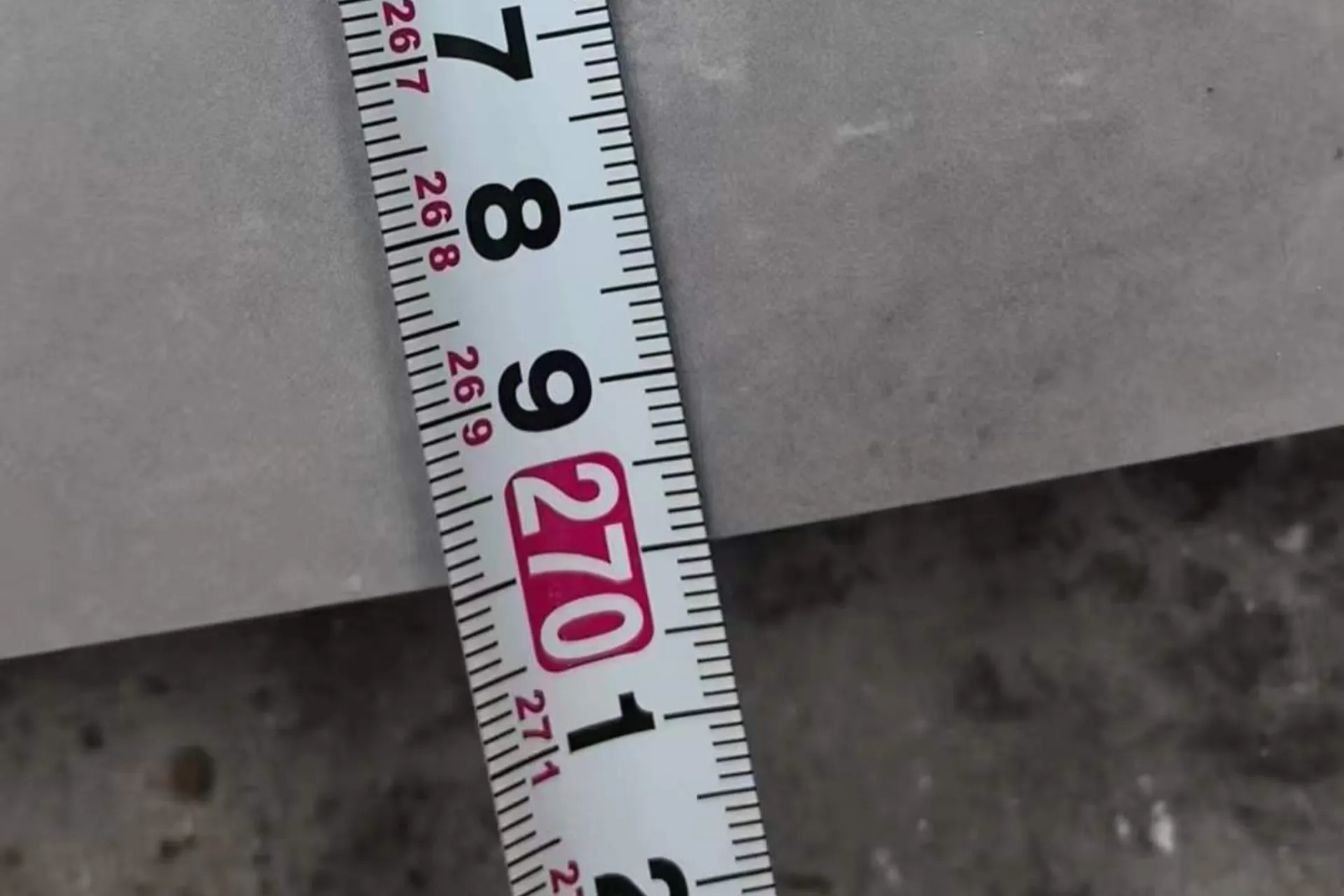

Dimensional Accuracy Testing

We scan slabs to ensure precise measurements, with length/width deviations ≤ ±0.5% and thickness deviations ≤ ±0.3 mm.

- Equipment: Laser Dimensional Measurement Device

- Testing Standard: ISO 10545-2

Surface Defect Testing

Using AI vision detection, slabs are meticulously inspected and guaranteed free from visible defects at a 1-meter distance.

- Equipment: Automated Optical Inspection Systems

- Testing Standard: GB/T 3810.5

Antibacterial Performance Testing

Surfaces are tested to ensure an antibacterial rate of ≥99% against harmful bacteria like E. coli and Staphylococcus aureus.

- Equipment: Bacterial Colony Incubator

- Testing Standard: ISO 22196

Flexural Strength Testing

We simulate wet and dry conditions to ensure a dynamic friction coefficient ≥0.45, providing reliable anti-slip safety.

- Equipment: Inclined Plane Friction Tester

- Testing Standard: DIN 51130

7 Performance Metrics That Prove Our Product Quality

We produce only the finest sintered stone — your projects deserve the quality to stand the test of time.

≤0.05% Water Absorption

Our sintered stone’s ultra-low double-zero water absorption ensures superior resistance to water damage, mold, and stains.

Heat Resistance Up to 1600°C

With heat resistance reaching up to 1600°C, our sintered stone is certified A1-grade in fireproof performance, making it a safe and reliable solution for high-temperature environments.

Flexural Strength ≥50 MPa

Our sintered stone offers an extraordinary flexural strength of ≥50 MPa, ensuring resistance to cracking or deformation under pressure, making it ideal for load-bearing surfaces and heavy-duty applications.

Anti-Stain and UV Resistance

Our self-developed surface technology ensures strong anti-stain properties and UV resistance, retaining vibrant colors and flawless finishes, even in high-use environments or prolonged sunlight exposure.

Anti-Slip Safety (> R10)

Our sintered stone provides reliable anti-slip performance with ratings exceeding R10, ensuring safety in wet or slippery areas and minimizing the risk of accidents.

Antibacterial Efficiency ≥ 99%

Our sintered stone is created to kill 99 percent or more of bad germs like E. coli and Staphylococcus aureus, which will make the interiors and exteriors cleaner and safer.

Superior Surface Durability (PEI ≥ 4)

With a PEI durability score of 4+ or higher, our sintered stone is highly resistant to wear ability, and it could be used in high traffic areas which is hard in the most cases.

Double-Zero Water Absorption

Our sintered stone’s ultra-low double-zero water absorption ensures superior resistance to water damage, mold, and stains.

Heat Resistance Up to 1600°C

With heat resistance reaching up to 1600°C, our sintered stone is certified A1-grade in fireproof performance, making it a safe and reliable solution for high-temperature environments.

Flexural Strength ≥50 MPa

Our sintered stone offers an extraordinary flexural strength of ≥50 MPa, ensuring resistance to cracking or deformation under pressure, making it ideal for load-bearing surfaces and heavy-duty applications.

Anti-Stain and UV Resistance

Our self-developed surface technology ensures strong anti-stain properties and UV resistance, retaining vibrant colors and flawless finishes, even in high-use environments or prolonged sunlight exposure.

Anti-Slip Safety (> R10)

Our sintered stone provides reliable anti-slip performance with ratings exceeding R10, ensuring safety in wet or slippery areas and minimizing the risk of accidents.

Antibacterial Efficiency ≥ 99%

Our sintered stone is created to kill 99 percent or more of bad germs like E. coli and Staphylococcus aureus, which will make the interiors and exteriors cleaner and safer.

Superior Surface Durability (PEI ≥ 4)

With a PEI durability score of 4+ or higher, our sintered stone is highly resistant to wear ability, and it could be used in high traffic areas which is hard in the most cases.

1-Year Warranty, 3-Year Traceability: Quality You Can Rely On

When you choose BIGCC, you’re choosing unmatched support and reliability. From our 1-year warranty that covers free replacements for issues like cracking or glaze peeling, to a 3-year traceability system that tracks every sintered stone back to its production data, we’re always by your side—before, during, and long after your project is complete.